Friction Sheet

Price 150.00 INR/ Kilograms

Friction Sheet Specification

- Product Type

- Friction Sheet

- Type

- Sheets

- Material

- Nylon

- Shape

- Rectangular

- Working Temperature

- up to 120C

- Working Presssure

- upto 10 MPa

- Density

- 1.14 Gram per cubic centimeter(g/cm3)

- Thickness

- 1 mm to 5 mm

- Specialty

- Durable

- Color

- Green

- Application

- Brake Lining, Clutch Facing, Industrial Machinery

- Water Absorption

- Low

- Friction Coefficient

- 0.3-0.45

- Elongation at Break

- 20-50%

- Tensile Strength

- Above 80 MPa

- Hardness

- 83-85 Shore D

- Surface Finish

- Textured

Friction Sheet Trade Information

- Minimum Order Quantity

- 3000 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America, Australia

- Main Domestic Market

- All India

About Friction Sheet

We have marked a special position for ourselves in the market by manufacturing and supplying a qualitative range of Friction Sheet. Offered range prevent the sheet from the attack of micro organism and chemicals. Entire range is manufactured by using superior quality of raw materials. Our engineers designed these sheets according to international norms for ensuring flawless performance. We offer Friction Sheet to our clients at pocket friendly price.

Features:

- Low water absorption

- Light weight

- Temperature resistance

Further Details:

Quality References

CM 16, CM11, WASM 80, WAS 80, HC AF 216 GG, HC AF 211 GG

Durability and Performance for Industrial Engineering

Designed with advanced nylon composition, these friction sheets deliver outstanding durability and resistance to wear, making them ideal for rigorous applications. Their high tensile strength and controlled elongation guarantee consistent performance under mechanical stress. The unique textured surface improves grip, resulting in enhanced safety and operational efficiency, especially in automotive and industrial machinery uses.

Versatile Applications Across Industries

Whether you are replacing brake linings, upgrading clutch facings, or manufacturing specialized machinery, these friction sheets assure reliability. Suitable for high-stress environments, they perform well under temperatures up to 120C and pressures up to 10 MPa, making them a trusted choice for applications that demand persistent and stable friction characteristics.

FAQs of Friction Sheet:

Q: How are these friction sheets installed in brake or clutch systems?

A: These friction sheets are typically cut to the required dimensions and securely bonded or fastened onto brake lining or clutch facing surfaces, following equipment manufacturer guidelines to ensure optimal performance.Q: What benefits do nylon friction sheets offer over other materials?

A: Nylon friction sheets offer superior durability, low water absorption, and a reliable friction coefficient, which helps prolong component life and enhance safety in high-stress applications compared to traditional materials like rubber or leather.Q: When should I consider replacing my existing friction lining with this product?

A: Replacement is recommended when existing friction lining shows signs of excessive wear, reduced friction performance, or damage. This nylon sheets durability ensures longer service intervals, reducing the frequency of replacements.Q: Where can these friction sheets be used apart from automotive applications?

A: Besides brake lining and clutch facings, these sheets perform excellently as friction components in various industrial machinery, conveyor systems, lifting equipment, and other settings requiring controlled friction.Q: What is the manufacturing process of these friction sheets?

A: The sheets are manufactured through a controlled extrusion or compression molding process using premium-grade nylon, followed by surface texturing to enhance grip and finishing procedures to achieve uniform thickness and quality.Q: How does the products surface finish improve its usage?

A: The textured surface increases the sheets frictional grip, promoting smoother engagement and reduced slipping in dynamic environments, which is essential for safety and performance in brake and clutch systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

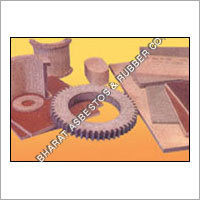

More Products in Asbestos Free Category

Twisted Rope

Price 152 INR / Kilograms

Minimum Order Quantity : 3000 Pieces

Product Type : Rope

Material : Other

Color : Yellow

Type : Other

Spitmaan Style AF 111

Price 155 INR / Kilograms

Minimum Order Quantity : 300 Pieces

Product Type : Spitmaan Style AF 111

Material : Rubber

Color : Orange

Type : Sheets

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry